(Please click the image to display)

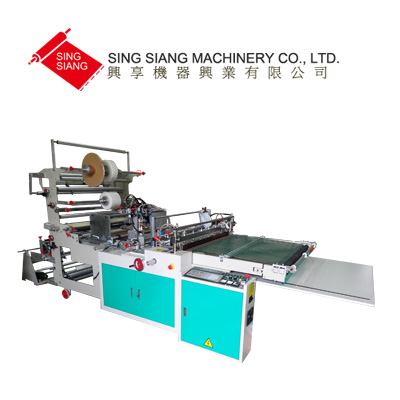

Special Feature:

1. Servo Motor Driven, Efficient mechanical structure produce 180 bags per minute.

2. User-friendly Control Panel, easy to understand easy to operate.

3. Digital control for production length adjusting, precise and less wastage.

4. Simple design, assemble precisely, durable, and easy for maintaining.

5. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch.

6. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically.

7. Universal Welding Device, easy operating and able to produce up to 15 kind of bag.

8. SHSS-T Twin Servo Motor Driven Model can produce two different size of printed plastic bag at same time.

• The Conventional mechanical clutch / brake and rack & pinion system is also available.

Optional Accessories:

1. Conveyer Stacker.

2. Ultrasonic Welding Device.

3. Punching Device.

4. Twin Bag Sealing Device.

5. Central Sealing Line Punch Device.

6. Rear Unwinder with EPC Device.

7. Perforated Line Roller.

|

Minimum production width

|

|

Standard Model

|

Min 50 m/m

|

|

Medium-Size Model

|

Min 35 m/m

|

|

Small-Size Model

|

Min 20 m/m

|

|

Model

|

SHSS-30

|

SHSS-36

|

SHSS-42

|

|

Output Cycle/min

|

Max 20 ~ 180

|

Max 20 ~ 150

|

Max 20 ~ 100

|

|

Bag Width

|

750 m/m

|

750 m/m

|

750 m/m

|

|

Bag Length

|

Max 750 m/m

|

Max 890 m/m

|

Max 1010 m/m

|

|

Servo Motor

|

One Set

|

|

Main Motor

|

2H4P

|

2H4P

|

2H4P

|

|

Inverter

|

3 HP

|

3 HP

|

3HP

|

|

Heater

|

2.5 KW

|

3.0 KW

|

3.5 KW

|

|

Power Consumption

|

4.0 KW

|

5.2 KW

|

5.7 KW

|

|

Machine Dimension (LxWxH)

|

4100 x 1420 x 1710

|

4100 x 1570 x 1710

|

4100 x 1720 x 1710

|

|

Machine Weight

|

1400 kg

|

1550 kg

|

1700 kg

|

|

Packing M3

|

8.5 m3

|

9.5 m3

|

10.5 m3

|

|

Gross Weight

|

1700 kg

|

1900 kg

|

2100 kg

|